Technological Developments Transforming the Automotive Silicone Industry

Modern vehicles demand materials that can withstand high thermal, mechanical, and chemical stresses while maintaining performance and safety standards. Automotive silicone has emerged as a critical component in meeting these requirements, widely used in seals, gaskets, adhesives, coatings, and electronic parts. The material’s versatility and durability make it essential for both conventional and electric vehicles, driving continuous growth in the Automotive Silicone Market. Manufacturers are increasingly adopting silicone solutions to ensure reliability, reduce maintenance costs, and meet evolving regulatory and environmental standards.

The automotive sector relies heavily on silicone-based components for thermal management and chemical resistance. Gaskets and O-rings made from silicone improve engine performance by ensuring leak-proof sealing and consistent performance under extreme temperatures. Adhesives and coatings enhance structural integrity and protect components against corrosion and environmental degradation. These applications are particularly critical in high-performance engines, hybrid powertrains, and electric vehicle systems where material reliability is vital.

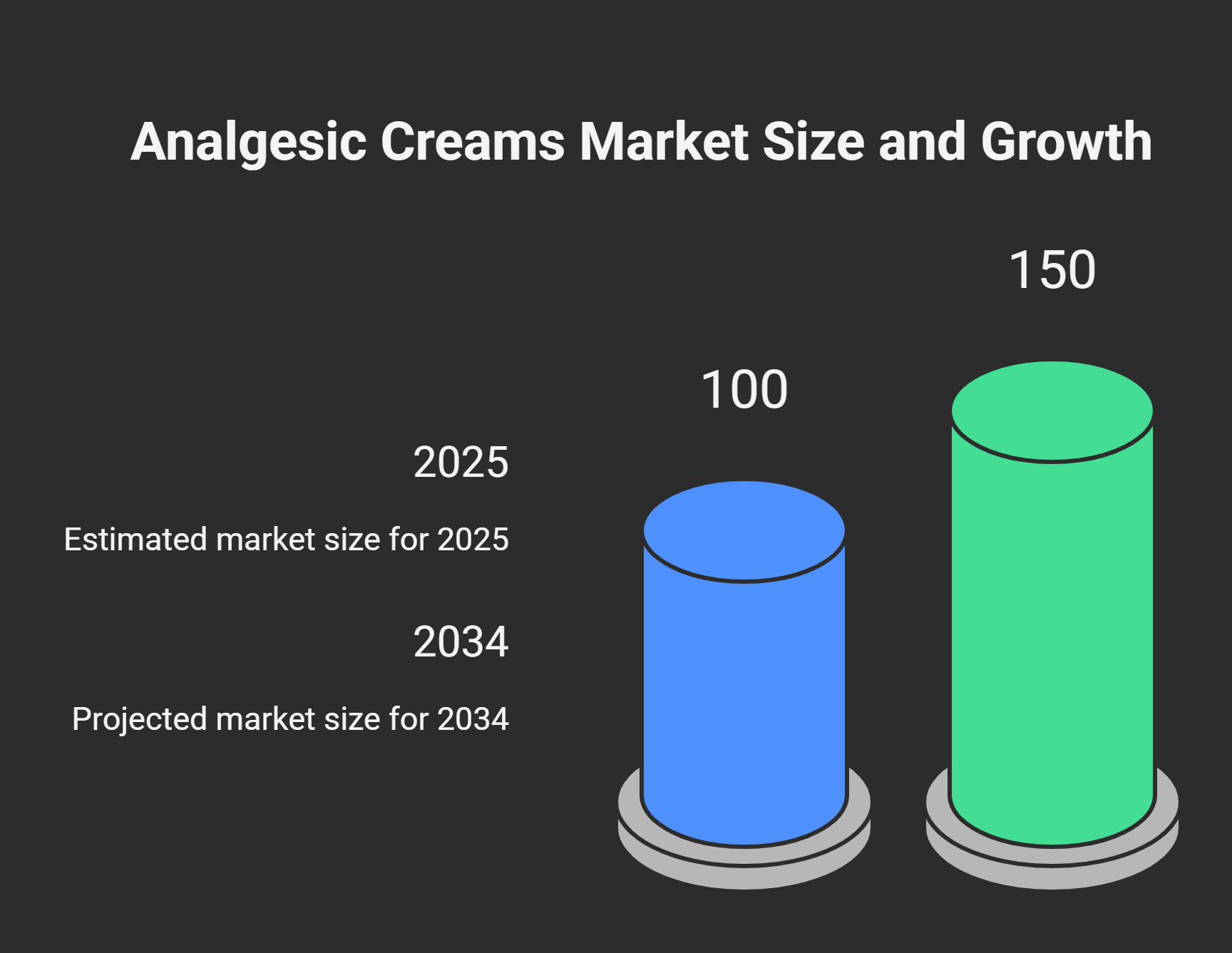

The shift towards electric mobility is accelerating the demand for automotive silicone. Battery systems, power electronics, and thermal management components require materials that perform reliably under extreme heat and voltage conditions. Silicone’s thermal stability, electrical insulation properties, and chemical resistance make it ideal for these applications. As a result, the Automotive Silicone Market is expected to experience robust growth, driven by increasing electric vehicle adoption, hybrid vehicle production, and advanced internal combustion engine designs.

Regional dynamics significantly influence market trends. Asia-Pacific leads in automotive silicone consumption due to its expanding automotive manufacturing base, growing electric vehicle market, and rising production capacities. North America and Europe continue to maintain steady demand with a focus on advanced vehicle technologies, regulatory compliance, and sustainability initiatives. Emerging markets are gradually scaling production to meet domestic and global demand, emphasizing the global growth trajectory of the automotive silicone industry.

Technological innovations play a critical role in shaping market evolution. Manufacturers are investing in research and development to create low-VOC, environmentally friendly silicone formulations with enhanced thermal conductivity, mechanical strength, and durability. Such advancements align with global sustainability initiatives while improving the performance and reliability of automotive components. These innovations also allow for application in emerging technologies such as autonomous vehicles, advanced driver-assistance systems, and smart mobility solutions.

By analyzing the Automotive Silicone Market and the Automotive Silicone growth forecast, businesses can identify market opportunities, optimize production strategies, and anticipate regional and technological trends. A comprehensive understanding of market demand, technological evolution, and regional dynamics allows manufacturers to make informed decisions, ensuring competitiveness in an increasingly complex automotive materials landscape. With continuous innovation and growing electric mobility adoption, the Automotive Silicone Market is poised for substantial growth in the near future.