Laser Processing Market Overview: Growth Drivers, Technologies, and Industry Applications

Laser technology has become an essential pillar of modern manufacturing and industrial processing. From precision cutting and welding to engraving, marking, and microfabrication, laser processing enables unmatched accuracy, speed, and efficiency. As industries increasingly adopt advanced manufacturing techniques, the laser processing market continues to expand, driven by innovation across automotive, electronics, medical, and aerospace sectors.

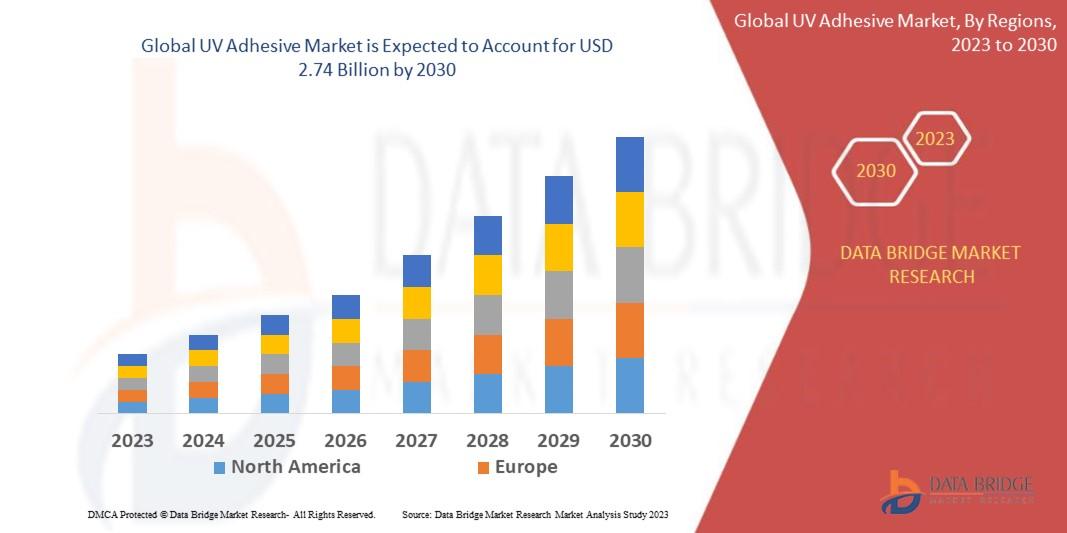

The laser processing market size is expected to reach US$ 6.46 billion by 2031, growing from US$ 11.26 billion in 2024, and is anticipated to register a strong CAGR of 8.4% during 2025–2031. This growth highlights the rising importance of laser-based solutions in high-precision and high-volume production environments worldwide.

Understanding Laser Processing Technology

Laser processing refers to the use of focused laser beams to modify materials through processes such as cutting, welding, drilling, marking, engraving, surface treatment, and micromachining. Unlike conventional mechanical methods, laser processing offers non-contact operation, minimal material waste, and exceptional precision.

These advantages make laser processing ideal for industries requiring tight tolerances, complex geometries, and consistent quality. As automation and digital manufacturing advance, laser systems are increasingly integrated into smart production lines.

Key Market Growth Drivers

One of the primary drivers of the laser processing market is the growing demand for precision manufacturing. Industries such as electronics and microelectronics require ultra-fine processing capabilities that traditional tools cannot deliver. Laser technology meets these requirements with high accuracy and repeatability.

Another major driver is the expansion of electric vehicles (EVs) and advanced automotive manufacturing. Laser welding and cutting are widely used in battery production, lightweight materials processing, and structural component manufacturing.

Additionally, advancements in laser sources—particularly fiber lasers—have improved energy efficiency, reduced maintenance costs, and expanded application possibilities, further accelerating market adoption.

Market Segmentation by Laser Type

Solid Lasers

Solid lasers, such as Nd:YAG lasers, are widely used in industrial applications due to their reliability and versatility. They are commonly employed in welding, drilling, and cutting applications across automotive and aerospace industries.

Despite facing competition from newer technologies, solid lasers remain relevant in applications requiring high peak power and pulsed laser output.

Gas Lasers

Gas lasers, including CO₂ lasers, have long been a staple of industrial laser processing. These lasers are particularly effective for cutting and engraving non-metallic materials such as plastics, wood, glass, and textiles.

Their established presence and cost-effectiveness ensure continued use in specific industrial and commercial applications.

Fiber Lasers

Fiber lasers represent the fastest-growing segment of the laser processing market. Known for their high beam quality, energy efficiency, and low maintenance requirements, fiber lasers are widely adopted in metal cutting, welding, and marking.

Their compact design and compatibility with automation systems make them ideal for modern manufacturing environments.

Others

This segment includes emerging laser technologies such as diode lasers and ultrafast lasers. These systems are gaining traction in specialized applications, including medical device manufacturing and microelectronics processing.

Market Segmentation by Configuration

Fixed Beam Systems

Fixed beam laser systems are commonly used in high-volume production environments where consistency and speed are critical. These systems are ideal for automated manufacturing lines and repetitive processing tasks.

They are widely adopted in automotive and electronics manufacturing facilities.

Moving Beam Systems

Moving beam configurations offer greater flexibility by allowing the laser head or workpiece to move during processing. This setup is suitable for complex geometries and customized applications.

Industries such as aerospace and medical device manufacturing frequently utilize moving beam systems.

Hybrid Systems

Hybrid laser systems combine fixed and moving beam capabilities, offering both precision and flexibility. These systems support a wide range of applications and are increasingly adopted in advanced manufacturing facilities.

Industry-Wise Market Applications

Automotive Industry

The automotive sector is one of the largest consumers of laser processing technology. Laser cutting, welding, and marking are used extensively in body-in-white manufacturing, battery production, and powertrain assembly.

The shift toward electric vehicles and lightweight materials continues to drive demand in this segment.

Electronics and Microelectronics

Electronics and microelectronics rely heavily on laser processing for PCB manufacturing, semiconductor processing, and component marking. The need for miniaturization and high precision makes laser technology indispensable in this industry.

Medical Industry

In the medical sector, laser processing is used to manufacture surgical instruments, implants, and medical devices. High precision, cleanliness, and consistency are critical, making lasers an ideal solution.

Aerospace Industry

Aerospace applications demand strict quality standards and material integrity. Laser processing supports the fabrication of aircraft components, engine parts, and structural elements with minimal thermal distortion.

Others

Other industries, including consumer goods, energy, and construction, also contribute to market growth through applications such as engraving, surface treatment, and component fabrication.

Competitive Landscape and Key Market Players

The laser processing market is highly competitive, with global players continuously innovating to enhance performance and efficiency. Key companies shaping the market include:

- LaserStar Technologies Corporation

- Jenoptik AG

- Fives SAS

- Coherent, Inc.

- Han's Laser Technology Industry Group Co. Ltd

- IPG Photonics Corporation

- TRUMPF SE + Co KG

- TE Connectivity Ltd

- Mitsubishi Electric Corp

- Lumentum Holdings Inc

These companies invest heavily in R&D, automation integration, and global expansion to strengthen their market positions.

Technology Trends Influencing the Market

Advancements in automation, artificial intelligence, and Industry 4.0 are reshaping laser processing systems. Smart lasers with real-time monitoring, adaptive control, and predictive maintenance capabilities are improving productivity and reducing downtime.

Ultrafast lasers and hybrid processing technologies are also expanding application possibilities in microfabrication and high-precision industries.

Future Outlook

The laser processing market is poised for sustained growth through 2031 as industries continue to adopt advanced manufacturing technologies. Increasing demand for precision, efficiency, and sustainability will further accelerate laser technology adoption.

Companies that invest in innovation, flexible system configurations, and industry-specific solutions will be best positioned to capitalize on the market’s expanding opportunities.

Related Reports

· Laser Distance Sensor Market Forecast, Trends, and Growth 2031

· Laser Therapy Market Trends and Analysis by 2031

· Laser Direct Imaging Market Size, Share, and Growth Analysis by 2031

· Laser Designator Targeting Pods Market Overview, Growth, Trends, Analysis, Research Report (2025-2031)

· Laser Ellipsometer Market Research Report by Size Share Analysis 2031

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients get solutions to their research requirements through our syndicated and consulting research services. We specialize in semiconductor and electronics, aerospace and defense, automotive and transportation, biotechnology, healthcare IT, manufacturing and construction, medical devices, technology, media and telecommunications, and chemicals and materials.

Contact Us:

If you have any queries about this report or if you would like further information, please get in touch with us:

Contact Person: Ankit Mathur

E-mail: ankit.mathur@theinsightpartners.com

Phone: +1-646-491-9876

Also Available in: 日本 | 한국어 | Français | لعربية< | 中文 | Italiano | Español | Deutsch